Manufacturing Unit Acceptance Check: Your Ultimate Guide High Quality Management Supplier Audit Programs

Data:

19 Settembre 2024

A Factory Acceptance Test (FAT) is crucial https://www.globalcloudteam.com/ in capital projects’ lifecycle, playing a significant role in industrial equipment quality and compliance. This check is carried out earlier than the gear is fitted on-site and is designed to validate whether the manufactured gear meets the pre-defined technical and functional specs. The FAT serves as a crucial high quality control measure, providing assurance to both producers and prospects that the product meets expectations. By conducting an FAT, you probably can identify and handle any issues or defects earlier than the product reaches the shopper, minimising the danger of costly rework, delays, or buyer dissatisfaction. A manufacturing high quality management checklist is a tool used to assist preserve standards by evaluating the standard of a product by way of weekly visual inspections of its measurement, color, weight, supplies used, and packaging.

Factory Acceptance Test Checklist: A Comprehensive Guide For Producers And Patrons

If the oil pump does not turn on, I must look into the wiring or my PLC logic. To take a look at this I can change the current and take a look at the HMI put in factory acceptance test definition on the panel to see if the indicator for the oil pump activates. Assuming that other ends of these terminals here are connected to terminals no 1 and a pair of, to test this enter I can put the signal simulator on the 4-20mA present mode after which join it to the opposite end of those terminals. To test the output, all you have to do is to activate the inputs utilizing simulated indicators and see if the contactor on the output will be energized. However, if the system is energetic, you should take a look at the wiring diagram and discover one of the simplest ways to simulate the signal coming from that energetic device.

Manufacturing Quality Management Guidelines

Factory acceptance testing is a crucial a part of the standard assurance course of. By conducting a radical FAT, the client can make positive that the equipment they are purchasing meets their wants and expectations. The pharmaceutical business uses a sort of FAT known as a Validation Acceptance Test (VAT).

Supplies And Cathodic Protection Techniques

Expedite and handle project vendors / contractors / 3rd parties in project. BrowserStack’s Test Management software addresses various challenges in User Acceptance Testing (UAT) and offers a robust platform for effective UAT. For Example, minor bugs may be reported alongside major practical points, making it difficult to focus on what needs fixing first. Identifying, prioritizing, and addressing points reported during UAT can be challenging.

Challenges In Person Acceptance Testing

Tests must be carried out to confirm that the supplies adjust to this Part of the Standard specification and all cables ought to satisfactorily pass such exams. Normally the FAT and EFAT cost are included in the procurement of the person gear. The SIT price estimation model for subsea manufacturing system is listed in Table 6-2. The planning workshops for the Factory Acceptance Test (FAT) and Site Acceptance Test (SAT) are typically scheduled during the project lifecycle’s Procurement, Implementation & Capability Building phase. The expertise involved in manufacturing is extremely advanced, and the know-how involved with documenting and tracking high quality on those processes has also improved dramatically.

Reveal Gear Performance

With a Factory Acceptance Test, you ensure that everything works properly before you deliver a control cabinet to a buyer. Obviously, there’s scope to be versatile, but the final goal as noted is to be efficient and ensure that the project understands the correct data to be included. During a factory take a look at for HVAC gear especially, the testing is normally accomplished underneath stringent situations inside a chamber that’s outfitted with instrumentation to permit distant monitoring and reporting of knowledge.

After the factory acceptance take a look at, tools delivery, and site installation, the consumer conducts a website acceptance test, ideally with the quality supervisor from the manufacturing facility. Use this guidelines as a tenet in conducting website acceptance exams and mechanically generate a shareable report the second you finish the SAT. Yes, a third-party inspector or expert can present an impartial and skilled assessment of the testing procedures and make certain that the equipment or system complies with industry standards, contractual requirements, and finest practices. This adds an extra layer of credibility to the FAT course of, enhances quality assurance, and instills confidence in the evaluation’s objectivity.

- For instance, let’s say that our analog enter card will receive 4-20 mA enter indicators from transmitters put in within the area.

- Make sure to obtain approval from all events concerned earlier than continuing with the cargo of the gear or system.

- And finally, testing have to be carried out in the manufacturing unit that follows specific test procedures.Before the FAT begins, the manufacturer ought to current the FAT process to the shopper for review and approval.

- Complete the security inspection with a cell device and ensure that equipment nameplates are seen, emergency cease buttons are accessible, and security switches are installed.

- Audits may be assigned to particular people or groups, and outcomes may be simply exported and shared with purchasers.

- For Example, information inconsistencies or configuration differences might trigger features to work appropriately in testing but fail in the manufacturing setting.

What’s Acceptance Testing? (importance, Sorts & Finest Practices)

The Factory Acceptance Test is efficacious for both end-users and manufacturers. It ensures the new tools meets all agreed-upon specifications, preventing points at the client’s website. Fixing manufacturing points earlier than the equipment leaves the manufacturer helps management the project’s timeline and finances. The FAT is a cost-effective answer, most well-liked over addressing points after deployment. By testing the equipment or parts before the shopper receives them, DXP can improve the odds that new installations will carry out as expected.

Guaranteeing the equipment’s performance, effectivity, and security demands a proactive approach, where due diligence reigns supreme. This is where the Factory Acceptance Test (FAT) steps in, acting as a critical checkpoint earlier than your machinery leaves the manufacturing unit floor. Specific standards might range relying on the trade and product kind and we’re familiar with all that apply. Common requirements include ISO 9001 for quality management systems and ASTM or ASME standards for mechanical tools. Industry-specific requirements and laws like FDA regulations for medical devices or ASME B31.three for piping systems may also apply. Our position is to make certain that the relevant requirements are met earlier than your product leaves your manufacturing facility.

During UAT, users validate that the system works as expected in real-world eventualities, identify any issues, and confirm that the software is prepared for deployment. Learn concerning the importance of User Acceptance Testing (UAT) and how it ensures your software meets consumer expectations and business requirements before release. Some contracts require a Factory Acceptance Test (FAT) conducted on the contractor’s facility; such a test consists of the contractor, or the system programmer specifically, demonstrating that this system logic works accurately. With the PCLDs and PPC factors lists in hand, the varied processes of the design are simulated and the operations are verified. The check is usually carried out with the completed panel, with the PPC and all terminations. Input indicators are jumpered to simulate the true world inputs; then the actions of the program logic are verified for correctness.

Once the procedure is approved, the producer should test the equipment before the FAT begins. Keep in mind that some shoppers like to visit the factory throughout FAT, so this “pre-test” will confirm that the sterilizer is ready up with the correct choices, ensure a smoother FAT process and reduce down-time during the FAT. An efficient way to eliminate inefficiencies in installing industrial gear is the vital thing practice of performing manufacturing facility acceptance testing (FAT). By simulating working and failure modes, every part of a system is checked earlier than leaving the manufacturing unit. This offers operators the opportunity to guarantee that the tools is working as supposed and provides them the reassurance that their top-quality tools will operate correctly from the get-go. Factory acceptance testing may even present guides to proper set up, enabling operators to optimize set up time.

Factory acceptance check protocols guarantee your gear is designed based on your specifications and can perform as anticipated. When you partner with ATC Automation, our skilled Design and Build team can carry out FATs to make sure your tools meets your specific needs. At ATC, we create extremely engineered automation techniques for a number of demanding industries. Whether you need an answer for meeting, material handling, or dispensing, we will create an efficient solution. When you purchase new tools, it’s important to make sure it will perform as anticipated after it arrives at your facility.

You will in the end pay the worth for this in longer start-ups and lost productiveness on the factory. Finally, the utilization of manufacturing unit acceptance test protocols will predict and proper issues which may have developed with area use. The function of FATs is to ensure that the system meets the entire specified necessities and is ready for ultimate installation and operational testing. The Process Operation Testing Checklist launched within the final part could probably be used as a basis for the FAT.

Ultimo aggiornamento

19 Settembre 2024, 23:05

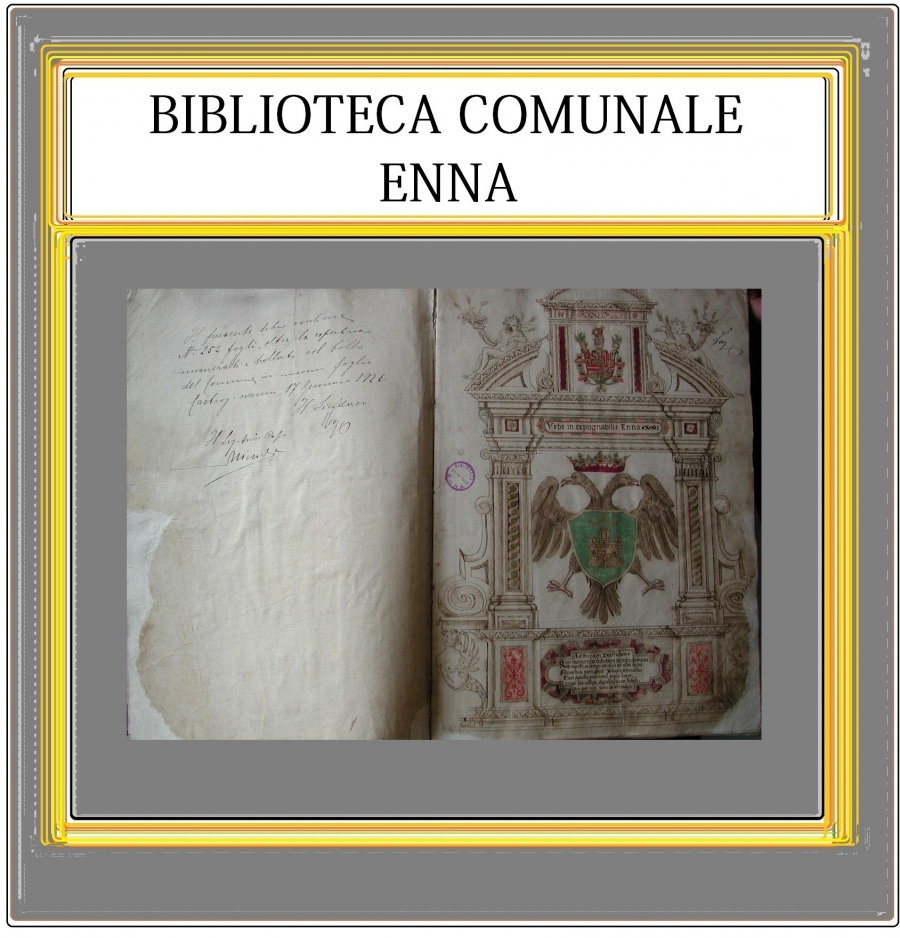

Biblioteca Comunale di Enna

Biblioteca Comunale di Enna